Our roots as a supplier of highly wear-resistant piping solutions lie in mining. In the nearly 75-year history of the company, many projects have been implemented in which the reliability and long service life of our TWIN PIPES are the basis for safe conveying from the silo or loading point to the underground backfill area – whether for transporting construction materials or conveying overburden for backfilling.

A distinction is made between upright and suspended versions of shaft pipelines. The pumped medium is usually conveyed pneumatically, but occasionally hydraulically, underground. Particularly in the case of suspended pipeline variants, strong forces act on the overall structure. Here, too, it is no problem for ESSER to provide the necessary structural analysis.

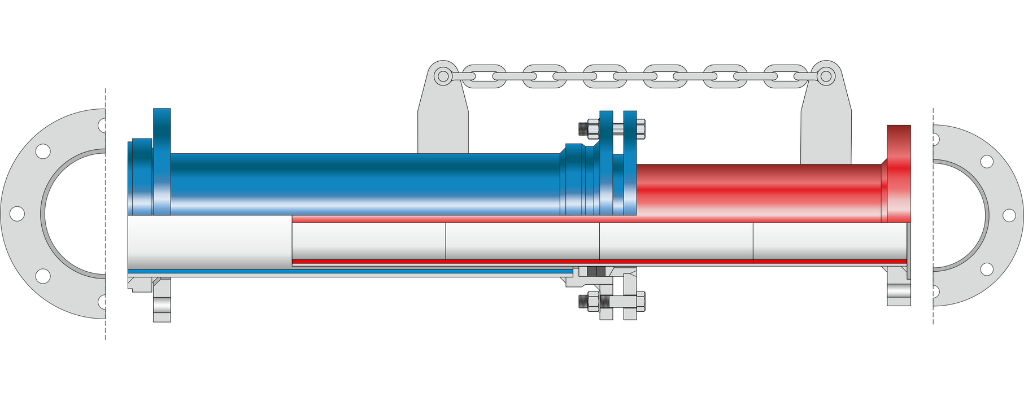

As is well known, temperatures rise with increasing depth, which results in expansion in the steel. To prevent damage to the shaft pipeline, we have developed special stuffing box expansion joints that can compensate for temperature-induced linear expansion within the production pipeline.

Diagram of pipe expansion joint

A widespread application is the laying of the pipeline through a borehole. ESSER offers special borehole couplings which, compared to flange connections, have a slim and stable design to fit through the borehole. This special design also reduces “jamming” when draining and passing through the borehole.

There are different variants for the further processing and transport of the various conveyed media. The most common include:

- Pneumatic backfill – the medium is pneumatically conveyed to the point of application.

- Hydraulic backfill – the dry medium is mixed with cement and liquid in a mixing plant before being conveyed hydraulically to the backfill area. This can be done by gravity or by heavy slurry pumps, which work with operating pressures of up to 200 Bar. Here, too, ESSER offers suitable piping solutions.

Pipeline components for the mining industry are generally manufactured in “heavy-duty design”. Safety, reliability, and long service life play a particularly important role since repairs are difficult to carry out due to the accessibility of the damaged area. The costs can be high, so line failure must be avoided as much as possible. Inspection times must be predictable and planned. ESSER supplies pipelines for mining in all available series (ESSER 160, ESSER 400, ESSER TWIN 700, ESSER TWIN 900).

Do you have a mining application where safe and reliable piping systems are needed? Let us become part of the solution. We will be happy to advise you.